Additive Manufacturing offers a multitude of advantages compared to conventional manufacturing methods like design freedom, shorter lead times or minimum tooling costs. However, up to now there have been only a limited number of commercial alloys available for Additive Manufacturing. Since the performance-requirements of the printed parts in several applications like tooling, aerospace and automotive industry are getting more complex in terms of mechanical properties and corrosion resistance, the powder materials for Additive Manufacturing processes also have to be improved.

AMPO – Additive Manufacturing Powder

Melting Routes:

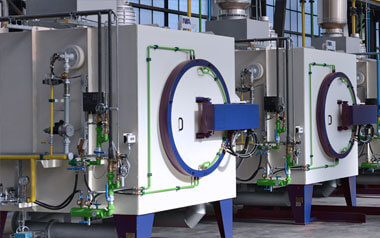

VIGA– Vacuum Induction Melting Inert Gas Atomization

EIGA Electrode Induction Melting Inert Gas Atomization